Single screw extruder design - Understanding Screw Design for Film Extrusion Process

In this case, the flow rate is known and equals the flow rate of the material metered into the extruder by the feeding device.

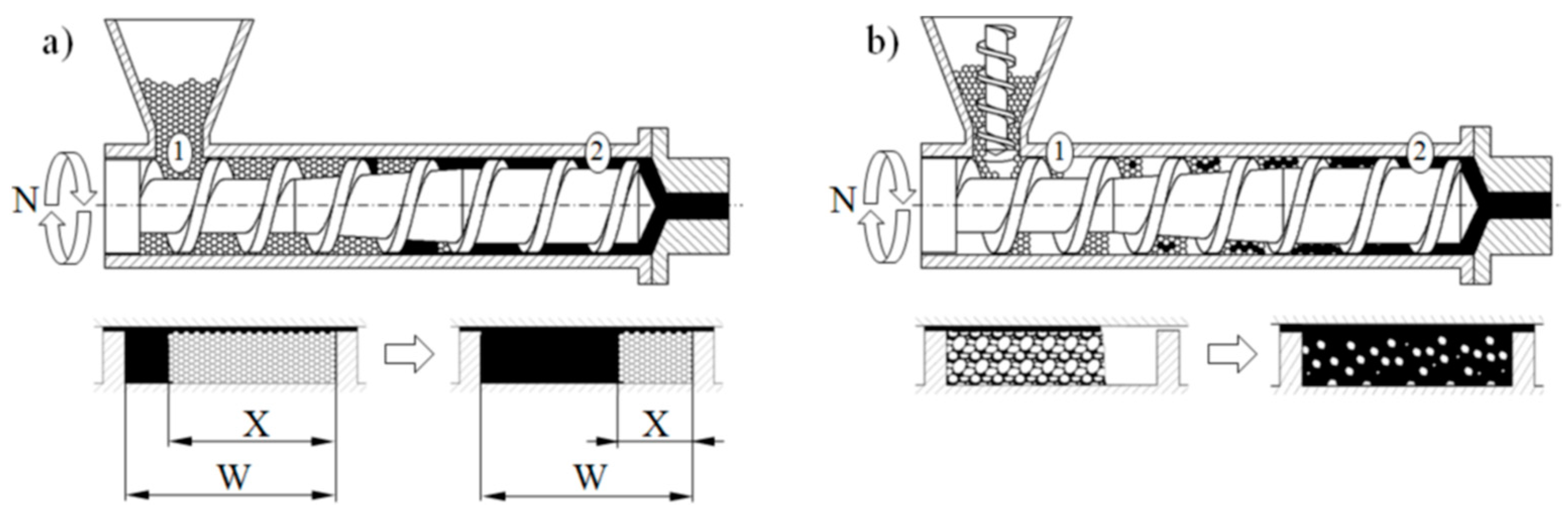

The lumped parameter concept is particularly useful when modeling the processes with polymer plasticization, e.

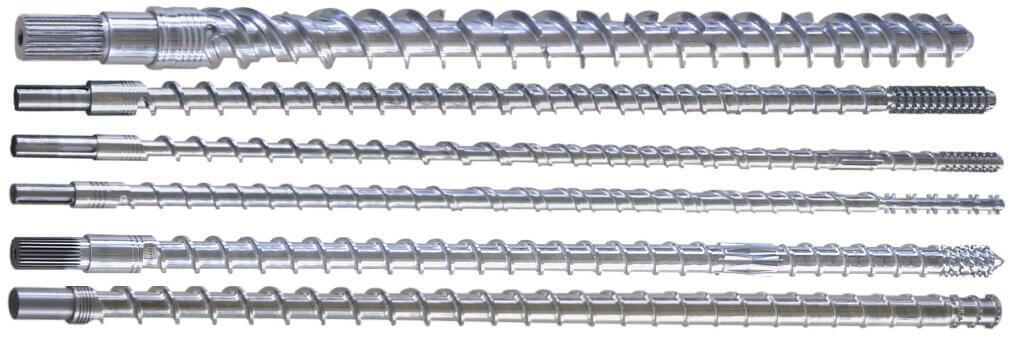

Single Screw Extruders

Today, these extruders assure greater production potential with more available energy through the unique design of the screw flighting and barrel ribbing.

Optima Single Screw

Studies on the modeling of starve fed single screw extrusion were much more limited.

Finally, development perspectives in this field have been discussed.

The second factor is the low required rotational speed of the extruder screw in this particular setup, caused by the limited displacement speed of the utilized build platform.

Understanding Melting in Single

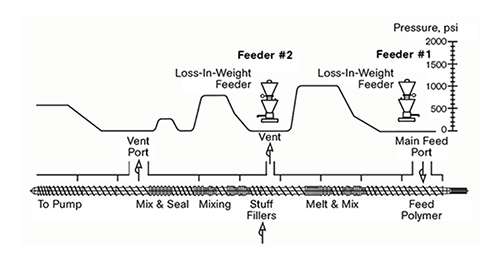

The screw is designed for processing of most polymers and has the same features as described for the non-vented version as well as: ¨ Vented screw design with Maddock mixing section at 15 D followed by the decompression and venting zone.

¨ Extruder head with chromed C-Clamp, equipped with two isolated handles and a single clamping screw for easy operation.

Understanding Melting in Single

The slope of the shear viscosity versus shear rate in this region, when plotted on double logarithmic scale, is used to determine the power-law index.

Description: Melting is hard to envision.

User Comments 3

More Photos

Latest Photos

Latest Comments

- +529reps

- To achieve this goal, it seems reasonable to apply the concept of using the optimization techniques based on the Genetic Algorithms to the minimization of discrepancies between the parameters of scaled processes, as in the case of scaling-up the conventional flood fed single screw extrusion and the co-rotating twin screw extrusion.

- By: Erfert

- +8reps

- ¨ Full steel cover over the entire extruder barrel with air venting grid on top.

- By: Halsy

- +922reps

- ¨ Digital programmable set and readout temperature controllers for all 5 zones 4 Barrels and one die zone coupled to solid-state relays for accurate heat control.

- By: Hesketh

- +233reps

- Water cooling is a more effective then air cooling, however tends to require more maintenance and in general more difficult to maintain.

- By: Cesare

- +54reps

- Optimization consists in obtaining a multidimensional space of process output variables response surface on the basis of an appropriate set of input data and searching for extreme values in this space.

- By: Pistol

DISCLAIMER: All models on adultporno.pages.dev adult site are 18 years or older. adultporno.pages.dev has a zero-tolerance policy against ILLEGAL pornography. All galleries and links are provided by 3rd parties. We have no control over the content of these pages. We take no responsibility for the content on any website which we link to, please use your own discretion while surfing the porn links.

Contact us | Privacy Policy | 18 USC 2257 | DMCA